Sealing Kombi Profile:

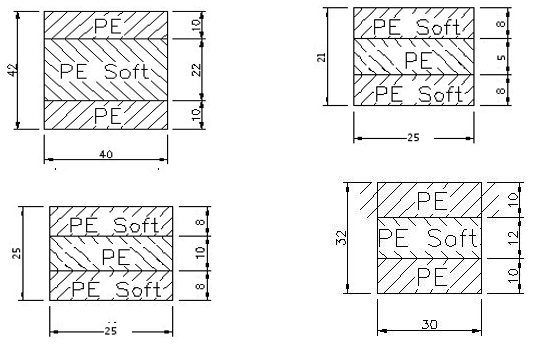

Sealing profiles Kombi: The Kombi Profile is made from two types of PE foam material. The outer layers of the profile are harder, and the inner layer is made of easily compressible “PE Soft” material, which returns to its original shape and thickness after decompression.

The lengths of individual sealing pieces are 1 or 2 meters.

Usage:

The Kombi Profile serves as sealing for log houses, air-tight filling of gaps between individual beams, and flexibly adapts to their irregularities. Moreover, compared to other sealing methods using only mineral wool or only wood wool, the Kombi profile does not tend to shrink (like wood wool) or settle (like mineral wool), thus the constructed houses show lower heat losses and higher thermal comfort in the long term.

Sealing the building using the Kombi Profile is significantly quicker, and material costs are lower than sealing the house using bound wood wool.

A key difference between the Kombi profile and mineral wool (inhalation of released micro-particles) lies in the health safety of the PE (Polyethylene) material used, both during construction and when the building is used by the end customer.

Installation:

The Kombi Profile can be placed between the beams directly when laying them, after the construction of the outer shell of the house, and it can also be added to the structure of the house fully loaded with the roof. In all cases, the profile adapts and reacts to later movements in the construction caused by changes in wood moisture. This profile is most commonly used together with strips of sheep wool 100mm x 40mm and a decorative surface strip, or possibly sisal or hemp rope – see photo.